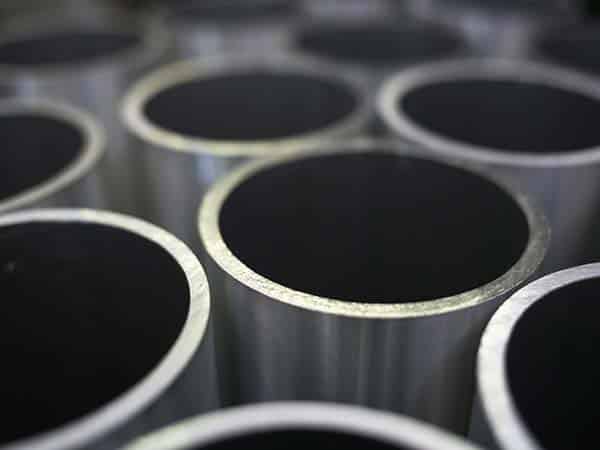

Processing of metals and other materials

Our precision mechanical workshop performs the processing of a variety of materials. Aluminium, iron, steel, brass, titanium and plastic materials (Peek, PVC, plexiglass…) are just some of the elements that, thanks to our know-how, we are able to process to professional standards.

We perform mechanical machining for chip removal on behalf of third parties, from traditional turning and milling, to multitasking turning and 5-axis milling.

Our production is capable of managing batches ranging from a few units to hundreds of pieces, from prototyping, to small batches in different sectors, from aerospace to motorsports. We take on the customer’s project and then work tirelessly to provide a complete and quality service.

The choice of materials, in the mechanical sector, is fundamental. Vierrevi srl is a partner for its customers, supporting them, when required, in the choice of the ideal materials for the rendering of the parts to be produced.

We also have an in-house department for milling from aluminium and plastic sheets. Thanks to the vacuum technology of our machinery, we are able to work with sheets measuring up to 2000 × 4000. Metals or plastic materials can be easily processed by our company aspirated surface milling machine, for the supply of large components, not normally feasible with traditional CNCs.

Request our services and contact us. We operate in the provinces of Parma and Bologna and throughout Italy and Europe.

The right material for every application

The large and well-stocked machine range combined with qualified personnel allows us to work with a variety of materials. The main ones are:

- Stainless steel (AISI 303, 304 and 316). It is a material that is particularly resistant to corrosion and heat, is easy to clean and involves low maintenance costs.

- Aluminium: particularly light, resistant and 100% recyclable.

- Iron: with exceptional mechanical resistance and widely used for mechanical machining.

- Copper, brass and bronze: these alloys are particularly flexible and are resistant to corrosion and fatigue.

- Inconel: it has high mechanical and corrosion resistance even at temperatures around 1200°C degrees; it is a material that is used in the aeronautical and/or aerospace field to build, for example, turbine blades for jet engines.

- Titanium: it is a light metal, well known for its resistance to corrosion and its high strength/weight ratio; the main area f use is that of the aeronautical and aerospace industry.

- PVC, plexiglass and plastic materials: ideal acoustic, thermal and electrical insulators, as well as being particularly light and versatile.

We accept new challenges

Flexibility in the processing of different materials at our mechanical workshop is just one of our strengths. This is how we have carried forward our corporate mission over the years: defying any challenge.

Request further information and contact us. We are here to guarantee you assistance and consultancy on every aspect. We offer our services in the provinces of Parma and Bologna and throughout Italy and Europe.