A highly structured mechanical precision workshop

For over 40 years the Vierrevi srl mechanical workshop has offered third-party mechanical precision processing. Our company is highly structured and divided into various departments, each of which specialises in its own particular area of expertise:

- Technical office;

- Turning department;

- Milling department;

- Marking department;

- Assembly department;

- Adjustment department;

- Testing department;

- Automated warehouse;

- Sales office;

- Production and planning department

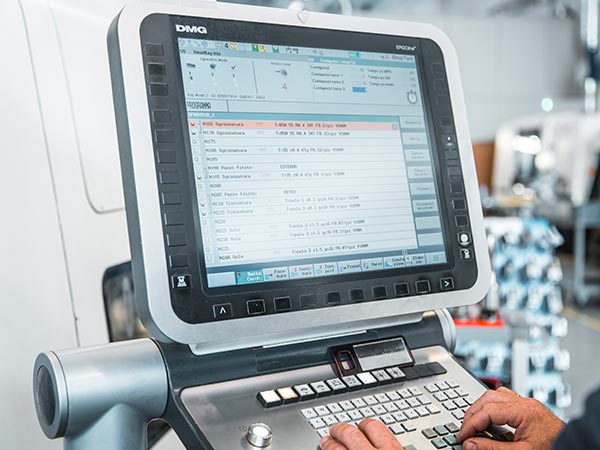

We study in detail the needs of the customer and we faithfully respect the indications they set out in the project. We use the best instruments including CAD-CAM programming software, schedulers and MES systems and we also create pieces with cutting-edge CNC machines.

We only use professional collaborators trained by the company, the purpose of which is to use just the one partner that we can trust with our experience. It is essential for us to offer industrial companies the best technologies available and to be able to guarantee our customers a working relationship with a partner of excellence. The task of our workshop is to perform each process as if it were unique, with the aim of achieving complete customer satisfaction.

We assure speed, quality and flexibility, and we are able to process not only metal components, but also plastic ones such as nylon and PVC. Our entire organisation is structured to guarantee a dynamic service which is split into several areas: we have a sales and customer care office dedicated to our customers that is able to guide them from the request for a quote to the tracking of raw materials and finished products, using our automated warehouses.

Request our consultancy and contact us. We offer our services in the provinces of Parma, Modena and throughout Italy and Europe.

TURNING DEPARTMENT

The turning department of Vierrevi srl specialises in the processing of parts with simple or complex profiles, from single pieces to entire small series. We work tirelessly, demanding quality and precision, thanks to stringent controls on the finished product and on all the intermediate stages.

MILLING DEPARTMENT

We perform milling operations to obtain a wide variety of profiles and surfaces achieved with the removal of material. The mechanical processes we operate are a reference in terms of quality, guaranteeing that all the specifications contained in the drawing are transferred to the actual item.

MARKING DEPARTMENT

We carry out a range of processes on mechanical components. The laser or percussion marking department allows the customisation and identification of the items according to the requests of our customers, including logos, batches and S/N.

ADJUSTMENT DEPARTMENT

Within our workshop, we run an adjustment department that specialises in the finishing of mechanical parts: here the items are finished, finding solutions to the issues that the mechanical machining for chip removal necessarily involves.

TESTING

Testing is an essential area that forms part of the process of creating precision mechanical parts. We perform quality checks to verify compatibility with the customer’s drawing, to determine the tolerances and to identify any dimensional anomalies.

AUTOMATED WAREHOUSE

The Vierrevi srl precision mechanical workshop uses the best technologies for the production of industrial components. We use state-of-the-art automatic vertical warehouses for the storage of raw materials, semi-finished and finished products in general.

Request the services of our mechanical precision workshop

For further information and to request our services contact us and send us your project: we will satisfy your every need. We operate in the provinces of Parma and Modena and throughout Italy and Europe.